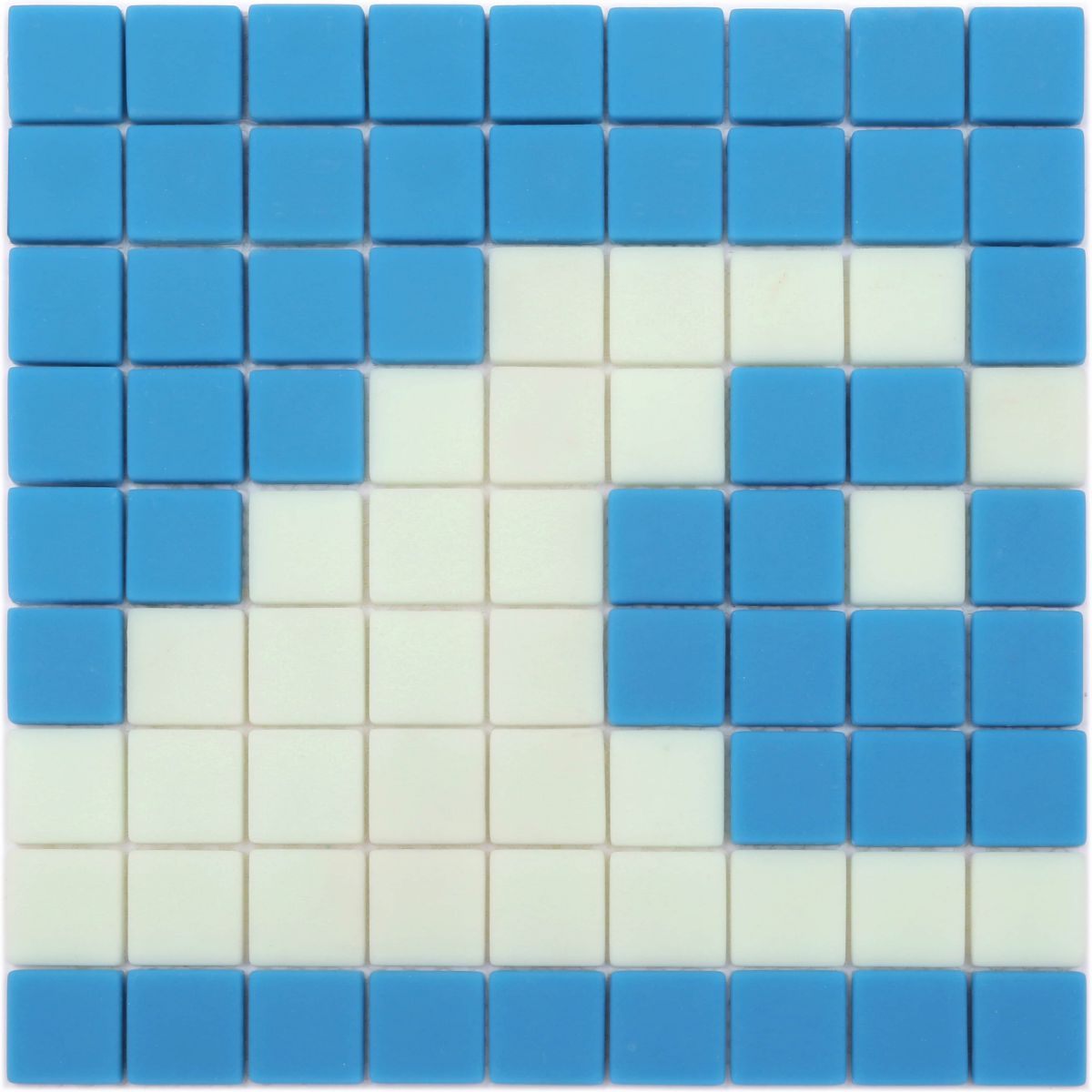

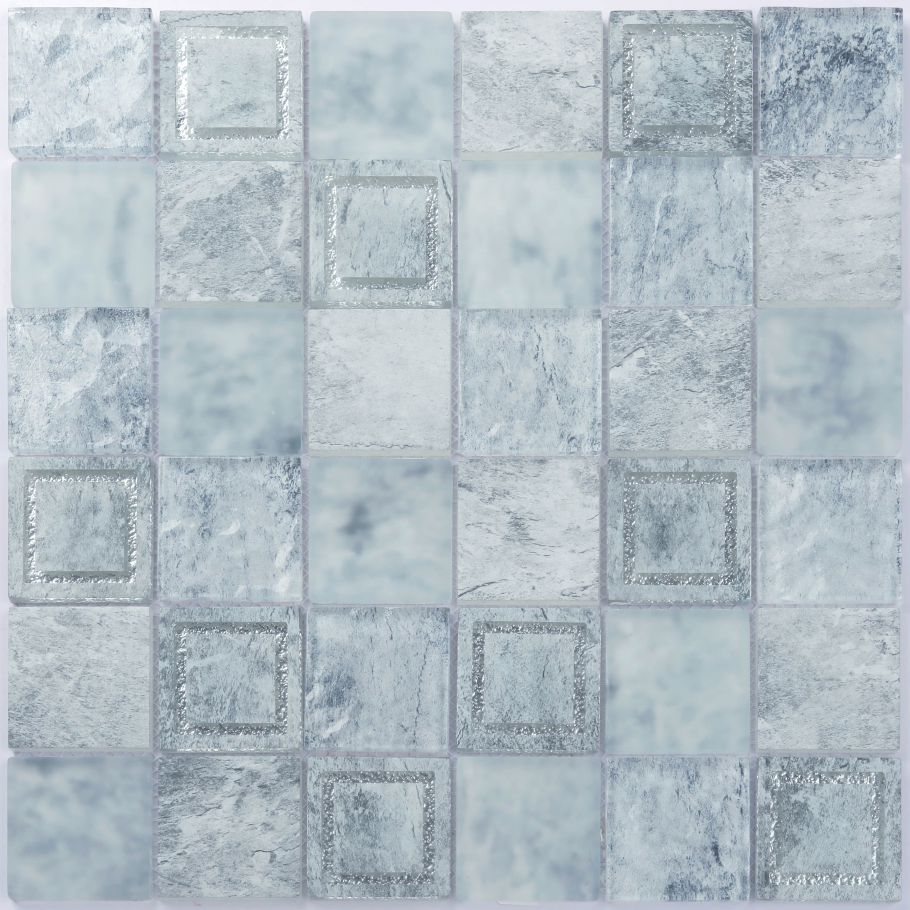

Swimming pool brick grout

Made from a variety of high-molecular polymers and high-grade pigments, it completely solves the troubles caused by white cement and caulking agent. It really makes your tile seams bright like porcelain, never dirty, and the coagulation agent solidifies. After the tile seam will form a smooth, porcelain-like clean surface, wear-resistant, waterproof, oil-proof, non-staining, excellent self-cleaning, not easy to hide dirt, easy to clean, wipe it clean, its Hardness, bonding strength, service life and other aspects are superior to caulking agents, which can completely solve the ubiquitous problem that the ceramic tile is dirty and difficult to clean. Whether it's just renovating a new paved tile seam or a tile seam that has been used for many years. Avoid gaps and molds that endanger human health. Performance characteristics

After solidification: 1. The surface is smooth as porcelain, high strength, wear-resistant, non-sticky, easy to clean, clean with a rub, avoiding cracks and molds endangering human health

2. It has the characteristics of waterproof, impermeability and oil-free, so that the tile seam will never be dirty.

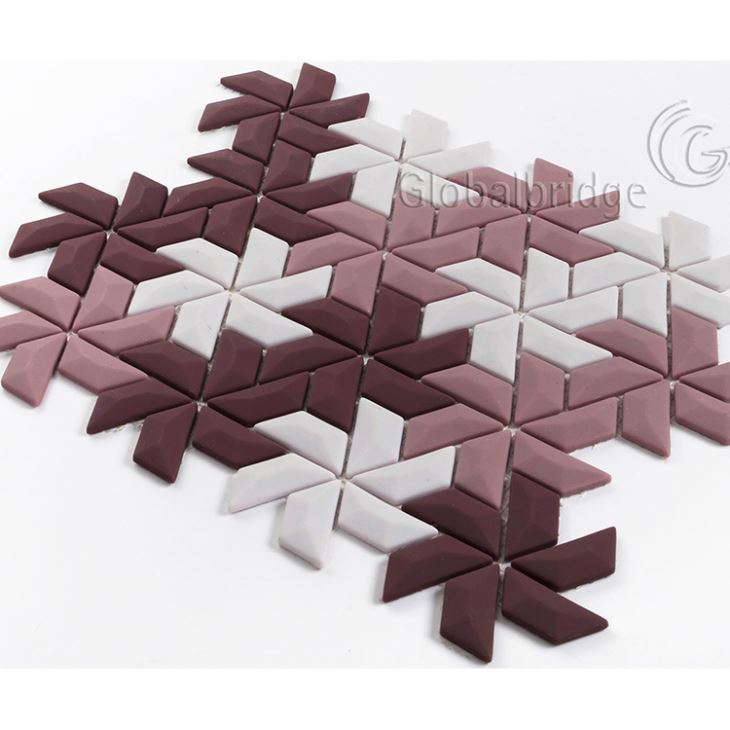

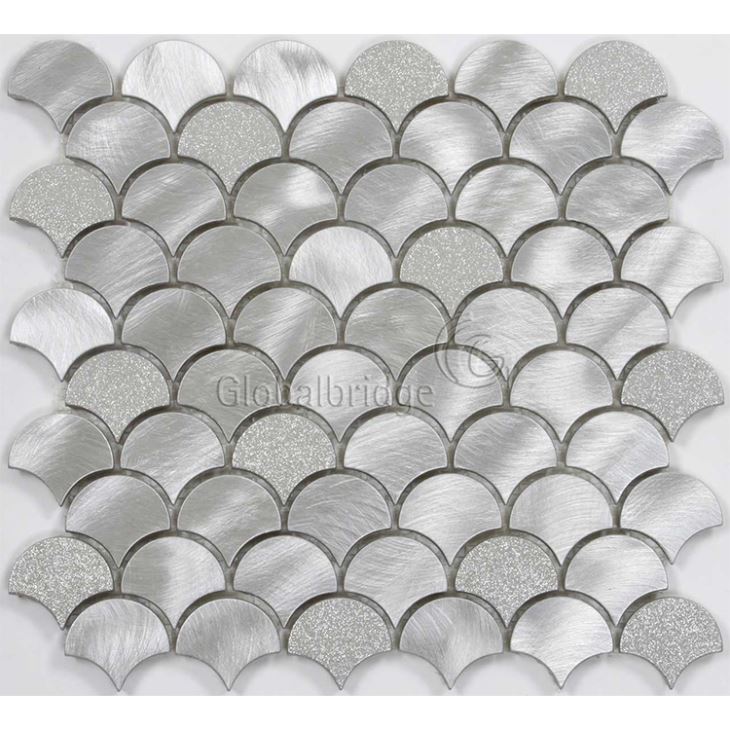

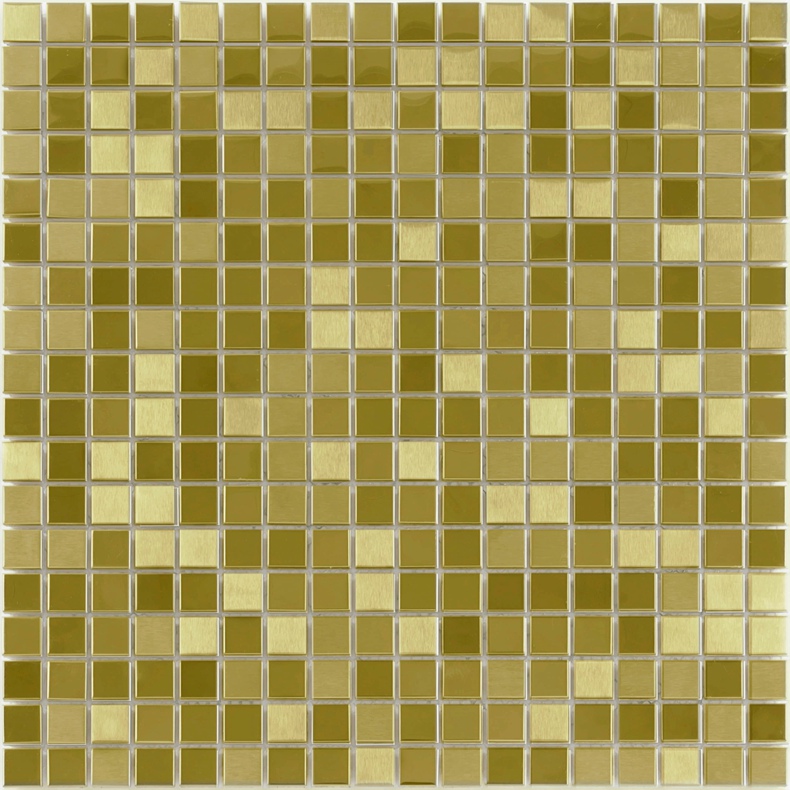

3. The decoration effect is particularly strong, the color is rich, the natural and delicate, the luster, the fading, and the wall surface brings a better overall effect. At present, there are common colors such as ivory white, black pearl, noble gray, enamel gold, moonlight silver, sapphire, and more high-grade colors such as strange and luminous.

4. Green, environmentally friendly, non-toxic, odorless, free of benzene, toluene, xylene. It meets the limit of harmful substances in the national standard GB18583-2001.

5. Convenient construction, simple operation, injecting brick joints, using a scraper or a finger. This product is semi-fluid, only with a rough surface, no smooth surface.

Swimming pool brick tile adhesive

The construction wall should be wet (external wet and dry), and maintain a certain degree of flatness. The uneven or extremely rough parts should be leveled with cement mortar and other materials; the base layer must be cleaned of floating ash, oil and wax to avoid affecting the adhesion; This product can be moved and corrected within 5~15 minutes after pasting the tile. The water-cement ratio is about 1:4, and the binder after mixing should be used up within 5~6 hours (the temperature is about 20 degrees);

Apply the mixed adhesive to the back of the tile and press firmly until it is level. Due to different materials, the actual consumption is different, generally about 4.5~6 kg per square meter, and the thickness is about 2~3mm.

English

English Español

Español